Do Meat Tumblers Save Money?

Do Meat Tumblers Save Money?

Meat tumblers that have a vacuum can save you a significant amount of time, labor, and money. By decreasing the marination time required, these machines reduce manual handling, refrigeration time, improve flavor consistency, and increase product yield. Whether you run a small butcher shop, a busy deli, or a mid-size processing facility, investing in a reliable meat tumbler can pay for itself through faster turnaround, less waste, and better quality control.

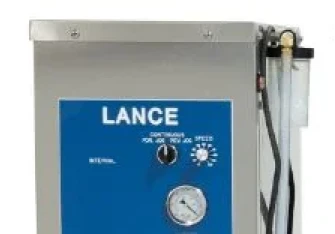

At Lance Industries, our tumblers are built to last and designed to perform. With durable construction, higher vacuum pull, and easy mobility, they help operators cut operating costs without sacrificing performance or quality.

While basic tumblers offer mechanical mixing, the cost-saving benefits discussed below apply specifically to vacuum meat tumblers, where reduced processing time, improved yield, and labor efficiency create measurable savings.

How Vacuum Meat Tumblers Help You Save Money

Every minute spent hand-mixing or waiting on traditional marination adds up — in labor, downtime, and energy. A vacuum meat tumbler eliminates that inefficiency. By using vacuum technology to pull marinades deep into the meat’s fibers, tumblers achieve full flavor absorption in a fraction of the time. The result? More consistent batches, higher yield, and faster throughput across your operation.

Here’s how the savings break down:

- Shorter Marination Cycles: What used to take days can be done in hours, freeing up staff and equipment for other work.

- Better Product Yield: Improved protein extraction minimizes waste and maximizes profit per batch.

- Energy Efficiency: Modern vacuum tumblers consume less power than older systems or manual refrigeration-based methods. As an example, a traditional marinade could take 12-24 hours, requires more refrigeration space, and consume more energy for cooling.

- Reduced Raw Material Costs: Vacuum tumbling improves flavor absorption, reducing brine, water, and seasoning use by up to 80%.

- Reduced Labor Costs: Automation means fewer hands and less time needed for prep.

Over time, these gains compound, lowering your cost per pound, increasing your yield, and giving your business more flexibility to reinvest in growth, quality, and innovation.

How Does a Meat Vacuum Tumbler Work?

Think of a meat vacuum tumbler as the smarter, faster way to marinate. Instead of letting meat sit in a brine for hours, the tumbler uses a rotating drum and powerful vacuum pressure to pull marinades deep into every cut. As the drum turns, it gently massages the product, helping flavors, moisture, and proteins move evenly through the meat in hours instead of days.

When the vacuum is applied, the pores of the meat expand. That negative pressure draws the marinade inside the muscle fibers instead of just coating the surface. The motion of the drum continuously flips and folds each piece, creating an even distribution of seasoning and a consistent texture from edge to edge.

The result? Tender, flavorful, and uniform meat that holds more moisture and weighs more after cooking, meaning higher yield and less waste. Without vacuum pressure, tumbling alone does not deliver the same reductions in marination time, labor, or yield improvement.

At Lance Industries, we’ve refined every detail to make that process as efficient and reliable as possible. Our tumblers pull a higher vacuum for deeper penetration, feature thicker steel drums that last longer, and are built with precision welds that don’t quit under pressure. It’s engineering that saves you time and boosts your bottom line, all while making your product look and taste better.

Key Areas Where Vacuum Tumblers Cut Costs

A meat vacuum tumbler delivers savings in more ways than one. Beyond faster marination, these machines streamline your entire process (from prep to cleanup) helping reduce overhead and improve profitability. Here are the main ways a vacuum tumbler can make a measurable difference in your bottom line:

Reduced Marination Time

Vacuum tumbling significantly accelerates flavor absorption compared to traditional soaking or brining methods. By using a controlled vacuum environment and mechanical action, marinades penetrate deeper and more evenly into the meat in far less time. Shorter processing cycles allow for increased production capacity, more batches per day, and reduced downtime between runs — all without sacrificing consistency or quality.

Lower Labor Costs

Manual marination requires hands-on time for mixing, transferring, and monitoring. A meat tumbler automates the process, freeing staff to handle other tasks or reduce overtime — a significant savings for small and medium processors.

Higher Product Yield

By opening the meat’s pores and improving protein extraction, vacuum tumbling enhances water and marinade retention. This results in juicier, more tender products and better yield after cooking, turning every pound of raw material into more sellable product.

Less Product Waste

Consistent marination reduces batch variability and spoilage. Operators get a uniform product every time, minimizing rework and wasted ingredients.

Energy and Maintenance Efficiency

Modern tumblers, like those from Lance Industries, are designed with efficiency in mind. They use durable components that require less frequent servicing and are energy-efficient to run. That means fewer repairs, lower utility bills, and a longer lifespan for your equipment.

When you add up the labor savings, reduced waste, and improved yield, the return on investment for a quality meat tumbler quickly becomes clear — it’s a tool that continues to pay off long after the first batch. Don’t take our word for it! Use our ROI calculator to see for yourself, how quickly your meat tumbler can improve your bottom line.

Comparing Vacuum Tumbling to Traditional Marination

Traditional marination relies on time and manual labor. Meat sits in a brine for hours and sometimes several days, with uneven flavor absorption and inconsistent yield. A meat vacuum tumbler replaces that slow, unpredictable process with precision and speed, delivering consistent results at a fraction of the cost.

The difference is clear:

| Category | Traditional Marination | Vacuum Tumbling |

|---|---|---|

| Processing Time | Long soak or brine periods required | Controlled tumbling cycles based on product type |

| Labor Involvement | High – frequent handling, mixing, and monitoring | Low – set parameters and automate the process |

| Flavor Penetration | Primarily surface-level absorption | Deeper, more uniform penetration throughout the cut |

| Product Consistency | Can vary between batches | Consistent, repeatable results |

| Yield After Cooking | Lower – greater moisture loss | Higher – improved protein binding and retention* |

| Waste & Rework | Additional marinade required | Precise amount of marinade use results in less marinade waste |

| Energy Usage | Extended refrigeration and storage time | More efficient processing cycles |

| Process Control | Limited precision | Adjustable vacuum, time, and drum speed |

| Equipment Durability | Tanks and mixers wear faster | Heavy-duty tumblers built for continuous use |

Tumbling times vary by product and formulation. Refer to Lance’s recommended tumbling procedures for product-specific guidance.

* Research phosphate adds to increase yield after cooking.

Real Savings for Small and Medium Processors

For many processors, it’s not just about producing great-tasting meat. It’s also about doing it efficiently and affordably. A vacuum meat tumbler helps smaller operations compete with larger facilities by improving workflow, reducing waste, and cutting production costs without sacrificing quality.

Small Food Processors and Butchers

Independent processors and butchers often face tight margins and limited space. A compact meat vacuum tumbler can dramatically improve productivity by reducing manual marination time and labor. Faster flavor absorption means more batches per day and less downtime. With less waste and more consistent quality, even small teams can deliver products that rival larger competitors.

Delis and Local Markets

For delis and local grocers, consistency is everything. Vacuum tumbling ensures that every batch of marinated meats tastes and looks the same, whether you’re preparing ten pounds or a thousand. Reliable marination helps reduce ingredient waste and minimizes the need for extra seasoning or rework, both of which cut into profits.

Medium-Sized Processors

Mid-level facilities benefit most from the scalability of industrial meat vacuum tumblers. Shorter marination cycles and reduced handling make it easier to manage growing demand without adding staff or floor space. Over time, the efficiency and yield improvements translate directly into lower cost per pound and higher output capacity.

Across the board, processors that switch to vacuum tumbling see a fast return on investment (often within months), as savings on labor, energy (savings through refrigeration real estate), and waste continue to add up with every batch.

Why Lance Vacuum Meat Tumblers Deliver the Best Long-Term Value

A meat vacuum tumbler is more than a piece of equipment. It’s an investment in your operation’s future. That’s why Lance Industries builds every tumbler to perform reliably for years with minimal maintenance and maximum efficiency. Each feature is engineered to help you lower costs, improve consistency, and get more from every batch.

Built for Durability

Lance meat vacuum tumblers use thicker-gauge stainless steel drums, heavy-duty frames, and precision welds that won’t break down under pressure. Fewer repairs and longer equipment life mean less downtime and lower ownership costs over time.

Higher Vacuum Pull for Better Performance

A stronger vacuum draw means deeper marinade penetration and shorter processing times. That efficiency translates directly into energy savings, faster output, and a better-tasting final product.

Moveable, Space-Saving Design

Every Lance tumbler is designed to roll through a 32-inch door. This mobility makes it easy to move the unit into walk-in coolers or tight workspaces, helping operators use existing space efficiently and avoid costly renovations.

Unmatched Customer Support

Our technicians are trained to keep your equipment running at peak performance. Whether you need troubleshooting or parts guidance, our fully stocked service department ensures you’re never left waiting, saving both time and lost production.

Proven Reliability, Trusted by Professionals

From small butcher shops to mid-sized food processors, Lance tumblers have earned a reputation for reliability, consistency, and value. Each model is backed by decades of industry experience and real-world testing.

With Lance, you don’t just buy a tumbler — you invest in lasting performance that continues to pay off, batch after batch.

Frequently Asked Questions

Ready to Start Saving?

When every minute and every pound of product counts, the right equipment makes all the difference. A Lance meat vacuum tumbler helps you save money by reducing labor, improving yield, and delivering consistent, high-quality results — batch after batch.

Whether you’re a small butcher shop, a local deli, or a growing food processor, our team is here to help you choose the model that fits your operation and your budget. With dependable performance, durable construction, and responsive service, Lance Industries makes it easy to get more out of every cycle.

Built to Last. Designed to Perform.

Contact our team today to learn how a Lance meat vacuum tumbler can start saving your business time and money.

If you’re looking for a reliable product at a competitive price, please call us at 1 (800) 775-2623 or email us to learn more about our massage tumblers and get a quote!